Category: How To

-

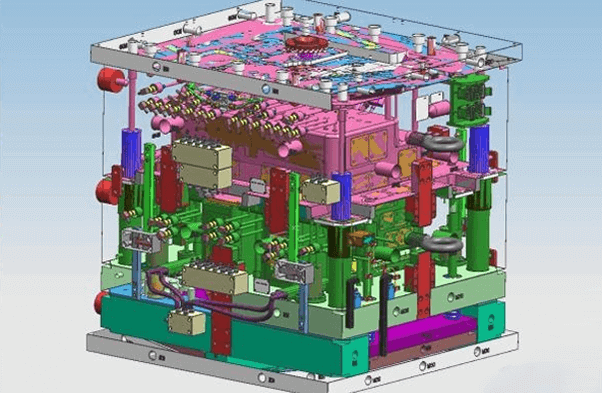

Plastic Injection Mold Design Guidelines in 2017

Designing Your Plastic Part When designing parts for injection molding, the manufacturing process is an important consideration. Injection molding is a process in which solid thermoplastic resin pellets are melted, injected into a mold, and then cooled back to a solid state in a new form. During Boss both the injection and cooling stages of…

-

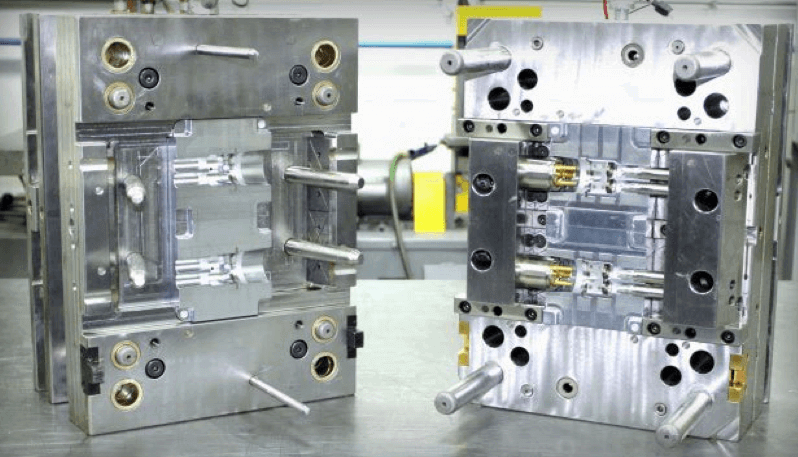

How to Choose a Reliable Plastic Mold Factory

How to find a reliable plastic mold factory? It has already become a pain in the neck for us to find a specialized mold maker that offers a reasonable and yet affordable price. Many are concerned that the quality of the product does not meet their requirements or the delivery is not punctual. With so…

-

How to Choose the Right Plated Coating for Improved Mold Performance

Many mold makers and molders have had great success with one particular coating and have used it for all of their applications. Unfortunately, there is not a magical coating out there that works in every situation. Many times, excellent coatings are used in the wrong applications. Speaking from a player’s viewpoint, one of the major…

-

How to Make Your Mold Shop Stronger

In March of 2001 the U.S. economy slid into a recession. By the time the powers that be decided to make the announcement in 2002 it was old news. Many organizations, including those in the moldmaking sector, had already taken a hard hit from the economic downturn, and were taking measures to survive long before…

-

Moldfolow Analysis Will Help Avoiding Potential Problem in Mold

Over the past two to three years, substantial advancements have been made in injection molding CAEsoftware. What started out as a tool to give designers a general idea of how a simple plastic part will fill, can now accurately analyze packing, cooling, warpage, fiber orientation in any complex part geometry and conditions in the mold. Identifying Problems…

-

More Plating Tips for Plastic Injection Molded Parts

There are many, many plating tips and secrets of the trade that one learns throughout the years. You may have heard some of these, but following are a few key pointers to keep in mind. They could save you a lot of time and aggravation down the road. Avoid using chrome when molding with polyvinylchloride (PVC). Chloride is…