Category: Technology

-

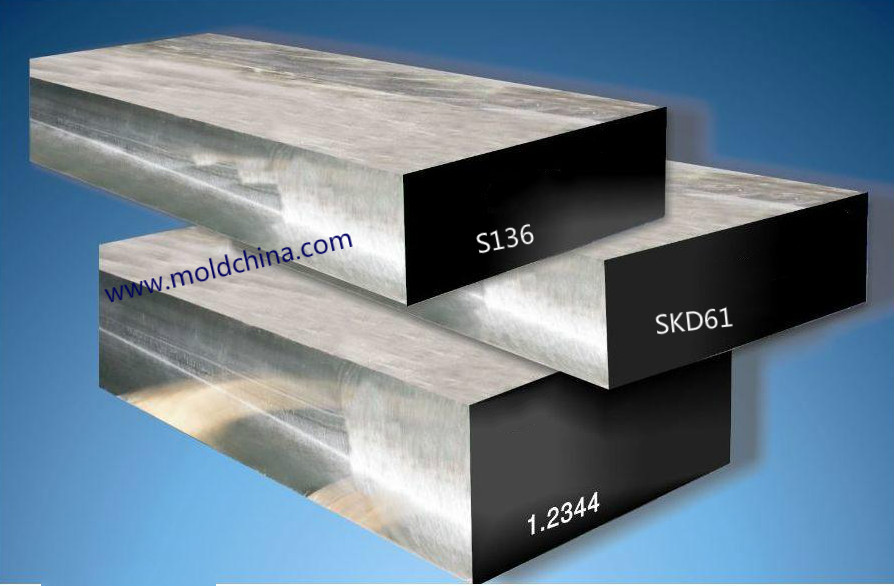

The steels for plastic injection mold

Due to the enormous diversity of plastic materials and the widely varied requirements for plastic products, various requirements for the performance of plastic injection mold steel have been laid down. Therefore, many industrially developed countries have created an extensive range of plastic mold steel series, including carbon steel, carburized plastic mold steel, aging hardening plastic…

-

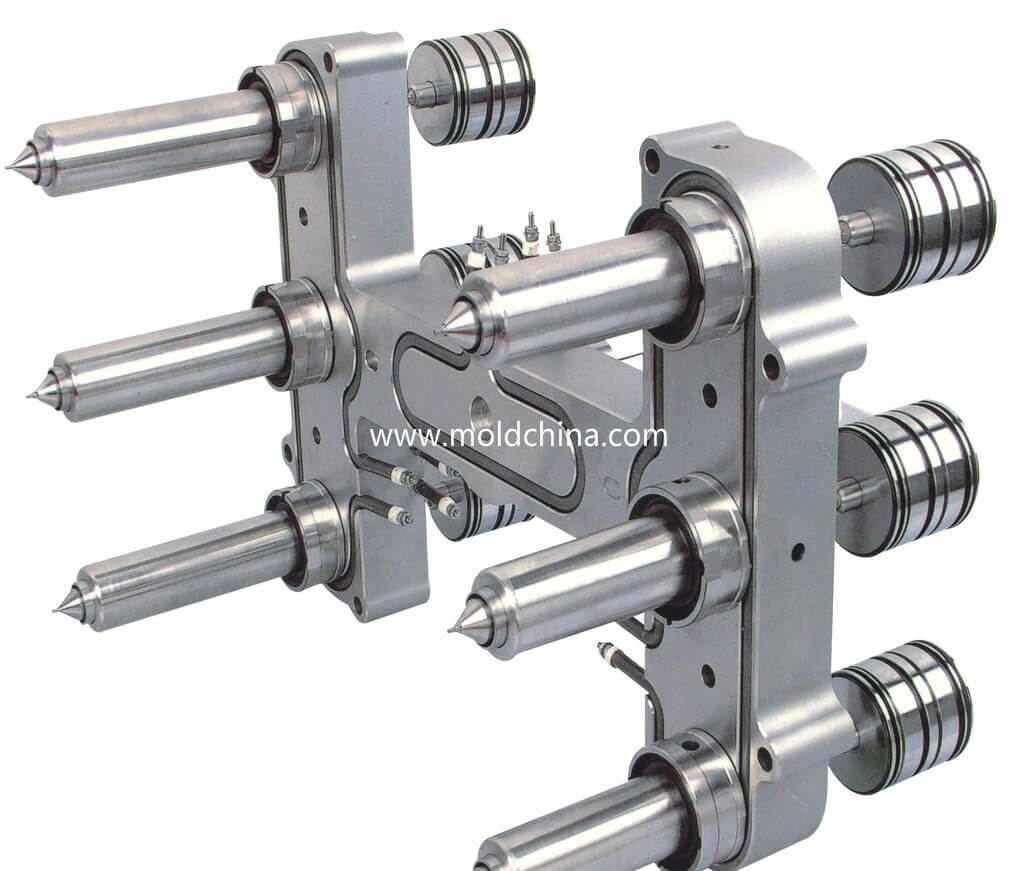

Hot runner system types and their application in plastic injection mold

1,How the Hot Runner System Works? The cold runner of a plastic injection mold refers to the section between the mold inlet and the gate. The molten plastic maintains its fluidity inside the runner by virtue of the injection pressure and its own heat. However, as a part of the molding material, the runner is…

-

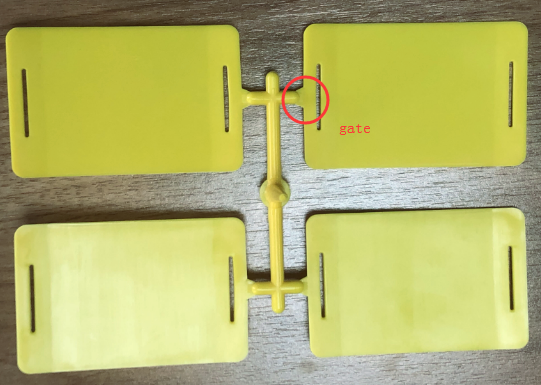

Plastic injection molding gate types

For plastic injection mold design, one of the most important factors is how and where the gate should be located. As the mold opening, the gate is where the molten plastic flows into the final part. It serves as the boundary between the part and the scrap, so its location, size, and shape play an…

-

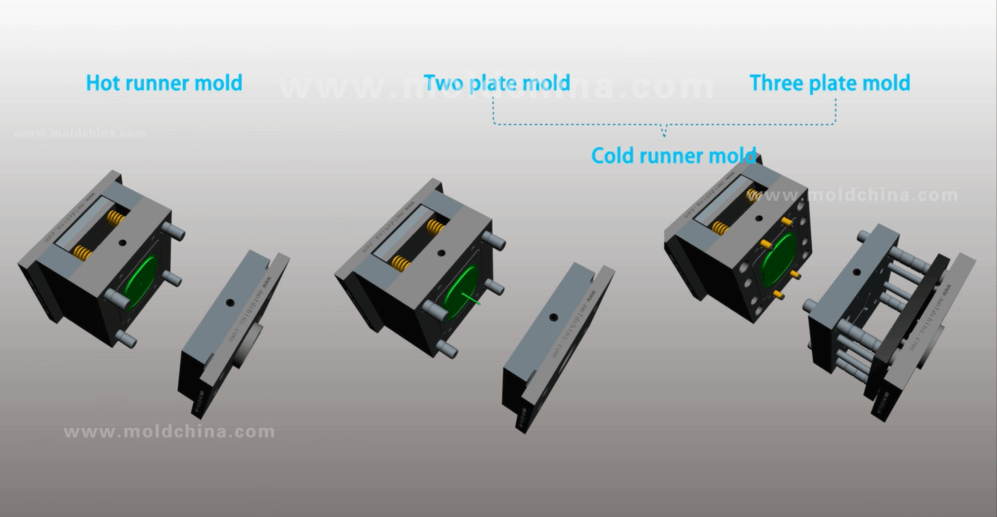

Hot runner mold vs Cold runner mold(Two plate mold vs Three plate mold)

Hot runner mold VS Two plate mold VS Three plate mold 1.Cold Runner Mold: Refers to the portion between the mold inlet and the product gate. The molten plastic is kept flowing in the runner under the effect of the injection pressure and its own heat. The runner only functions as part of…

-

Injection mold cooling system design

Definition of injection mold cooling system: Injection mold cooling system: AKA. injection mold temperature control system Heat or cool the mold to keep its temperature within a reasonable range. -Mold cooling medium: water, oil, beryllium copper (BeCu) and air, etc.; -Mold heating methods: hot water, steam, hot oil and heating rod, etc. Influence of Mold…

-

The texture for plastic injection mold

While our everyday life is filled with more and more plastic products, people start to be aware that they do not want them to look like “plastic” products. Therefore, the plastic injection molds decorated with the texture process are more welcomed because they cater to people’s interests. 【Purpose of Texture】 (1)Improve product appearance. The texture…

-

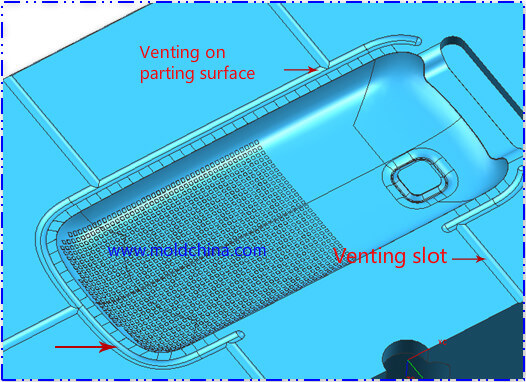

Why the venting is so important for a plastic injection mold?

The injection mold venting slot serves two purposes: 1. Expel air from the plastic injection mold cavity during the injection process of the molten plastic material; 2. Get rid of the various gases produced during injection molding processing. The setup of venting slots is of great importance, especially for thin-walled products or the locations far…

-

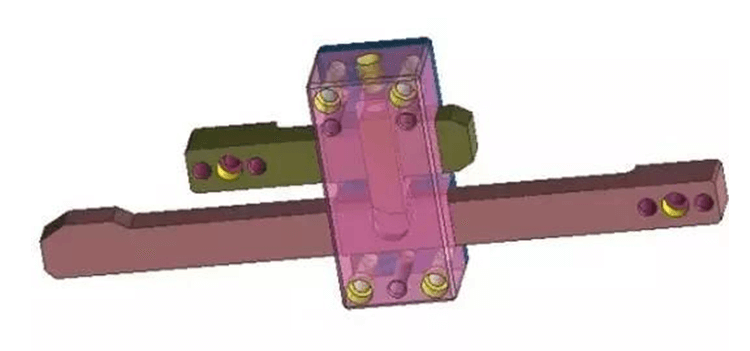

Latch lock

The Functions of a Latch Lock: In the two-step parting, two-step ejection or cavity ejection mechanism, a latch lock unit is always employed to control the opening sequence and stroke of each mold plate. Though latch locks perform similar functions, they have a diversity of different structures. So, it is necessary to select the…

-

Injection molding machine operation instruction and good habit

1.A great habit of injection molding machine operation is of enormous benefit to both machine service life, as well as production safety. (1)Before the Machine Starts ①Check to see whether there is any water or oil inside the electrical control box. Don’t turn it on if the machine is affected by moisture. It can only…

-

Surface roughness -injection molding defects

Surface roughness means there is a lack of precision in the surface of a molded part, or an inconsistent level of precision all over the surface, e.g. some areas are glossier than the rest. The main reasons for surface roughness might lie in the injection molding machine, the mold, the process or the material. (1)Injection…