Product: Headset band

Material: PC

No. of Cavity: 1X1

Product Characteristics: Simple shape, complex structure, with minimized parting line.

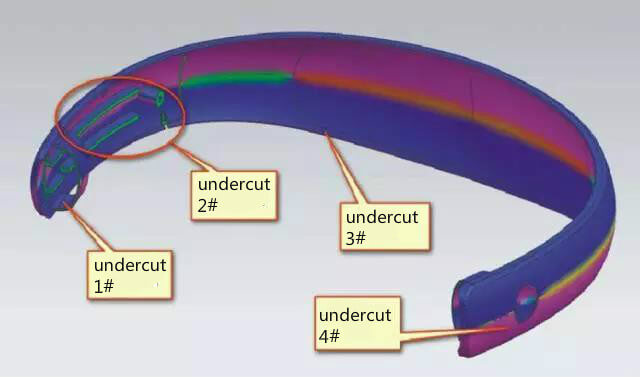

1.First of all, perform slope analysis. The following figure shows that the plastic injection mold has 4 undercuts.

2.The following figure shows that the mold has another 3 undercuts. That’s 7 undercuts in total

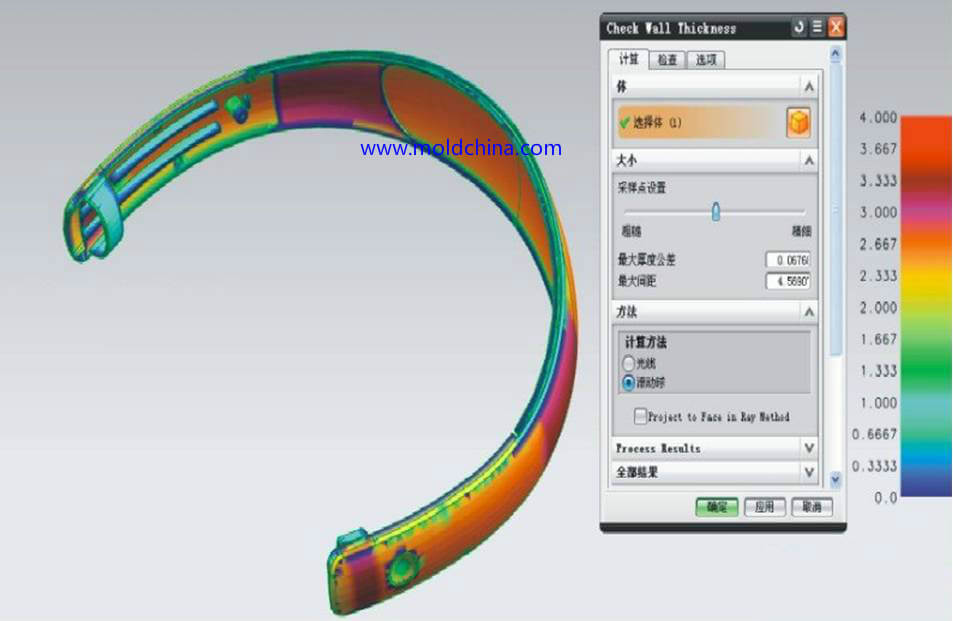

3.According to thickness analysis, the basic wall thickness of the product is 2.3mm.

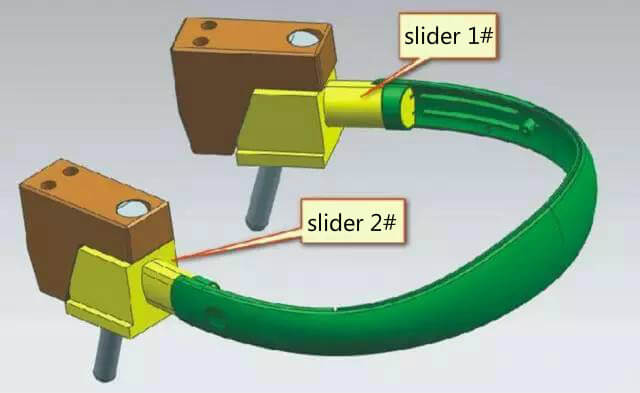

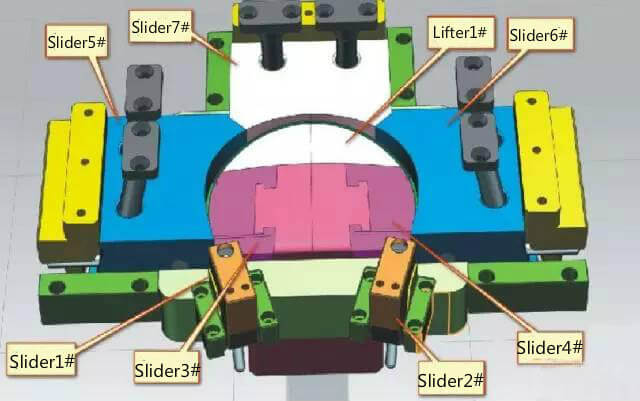

4.It is determined that 2 sliders are placed at undercut 1 and undercut 6 respectively (slider 1 and slider2).

5.Undercut 2 and undercut 5 are located inside the product, so inner sliders are applied, which will work with the mold base and the 1 more plate for 2-stage ejection.

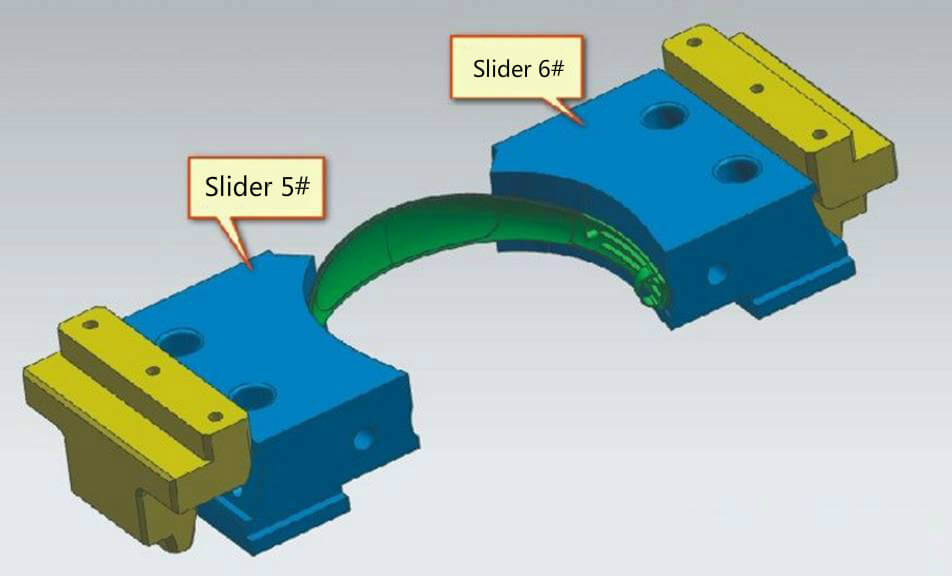

6.It is determined that undercut 4 and undercut 7 will be released through the application of slider 5 and slider 6.

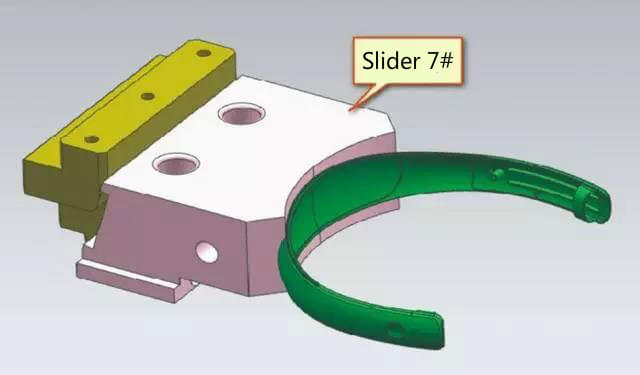

7.There is no undercut at the location of slider 7, but the slider is applied to meet the requirements for minimized parting line.

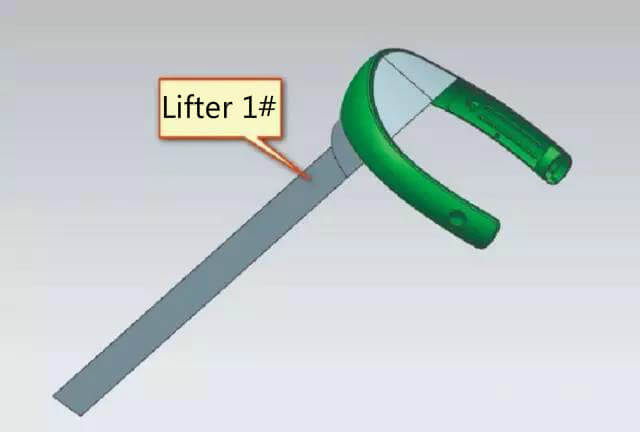

8.Undercut 3 adopts the lifter design for release. Since it is surrounded by sliders, undercut 3 is subject a weak clamping force, so ejection will be performed by the lifter.

Through an overall review of the mold, we can come to the conclusion that this a very simple product with a very complex structure. In total, 7 sliders and a lifter are employed.