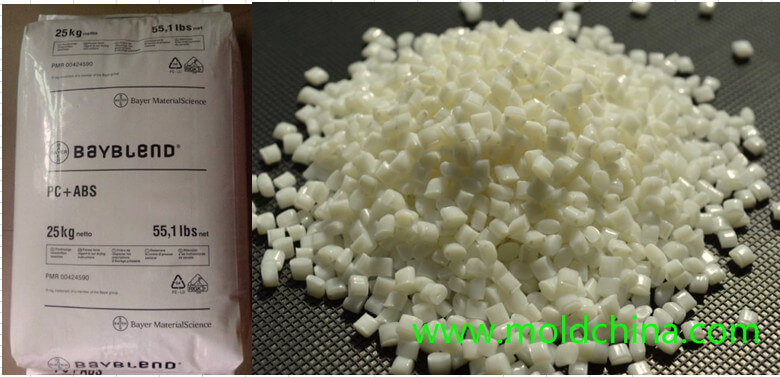

What is the PC/ABS?

PC/ABS is a blend of PC (polycarbonate) and ABS (acrylonitrile-butadiene-styrene copolymer), and a thermoplastic made of the polycarbonate and ABS alloy, offering the most desirable properties of the two materials – the processability of ABS and the mechanical properties, as well as resistance to impact, temperature and UV of PC. It can be widely used in automotive internal parts, business machines, communication equipment, home appliances and lighting fixtures. Typical applications include computer and business machine housings, electrical equipment, lawn & gardening machines, automotive parts / dashboards, interior finishes, and wheel covers).

Injection Molding Process Conditions: Drying before processing is a must. The humidity should be kept below 0.04%. The recommended drying condition is 90°C-110°C for 2-4 hours. Melting temperature: 230-300°C. Mold temperature: 50-100°C. Injection pressure: depending on the plastic product. Injection speed: as high as possible.

Chemical and Physical properties: the PC/ABS injection molding material combines the properties of both PC and ABS. For example, the easy processability of ABS, and the excellent mechanical properties and thermal stability of PC. The ratio of the two will affect the thermal stability of the PC/ABS material. The blend of PC/ABS also shows excellent fluidity. The shrinkage rate is around 0.5%. PC/ABS is a modified engineering plastic synthesized by blending. Among them, PC refers to polycarbonate, and ABS refers to the copolymer of acrylonitrile (A), butadiene (B) and styrene (S). This modified plastic boasts a better performance than pure PC and ABS, such as the improved resistance to impact and heat, as well as the increased hardness.

The characteristics of the PC/ABS injection molding Material:

- The fluidity is a little lower than that of HIPS, but better than that of PMMA and PC, etc., while the flexibility is great.

- Highly resistant to impact and heat, flame retardant (V0 flammability rating), enhanced properties, and transparent.

- Great weldability with the 372 plexiglass, allowing production of two-color plastic parts, able to be chrome-plated and painted.

- Outstanding overall performance, high resistance to impact, chemical stability and great electrical performance.

Applications: Computer casings, computer components, typewriter casings, cameras, mobile phones & other business machine housings, electrical equipment, electrical & electronic parts, small household appliance components, hair dryers, connectors, word processors, medical equipment components, office supplies, cosmetic containers, food plates, lawn and garden machines, automotive headlamp frames, taillight covers, dashboards, interior finishes, and wheel covers, etc.

Plastic injection molding processing Conditions of the PC/ABS Material:

Drying Temperature: 104-110°C

Drying Time: 3.0-4.0h

Suggested Injection Volume: 30-80%

Suggested Max Water Content: 0.040%

Barrel Temperature: 60-80°C

Barrel Rear Temperature: 249-288°C

Barrel Center Temperature: 254-293°C

Barrel Front Temperature: 260-302°C

Injection Nozzle Temperature: 274-302°C

Processing (Melt) Temperature: 274-302°C

Mold Temperature: 60-87°C

Back Pressure: 0.345-0.689Mpa

Screw Speed: 40-70RPM

The amorphous thermoplastic blend of polycarbonate/acrylonitrile butadiene styrene (PC/ABS) is highly resistant to impact, with easy plasticity at low temperature. With excellent resistance to impact and heat, as well as excellent aesthetic and coloring effects, the Cycoloy resin blends can be tailored to meet the requirements for specific properties, so as to balance performance, cost and processability. The outstanding appearance and durability of the Cycoloy resin blends are very important for them to offer excellent design solutions.

Applications:

PC/ABS is a injection molding thermoplastic made of PC and ABS alloy, combining the excellent properties of both materials. It can be widely used in automotive trims, lampshades, handles and other parts; consumer and commercial appliances, such as computers; and peripherals, such as mobile phones; able to replace PC for production of thin-walled products with long running processes; camera components, instrument panels, fan covers, hard hat housings, screw caps, radiator grilles, computer and optical instrument housings, hair dryers, and coffee makers, etc. PC/ABS manufacturers include SABIC Innovative Plastics, Bayer (Germany), Chimei (Taiwan, China), Teijin (Japan), LNP (the US), LG (South Korea), and Mitsubishi Engineering (Japan)