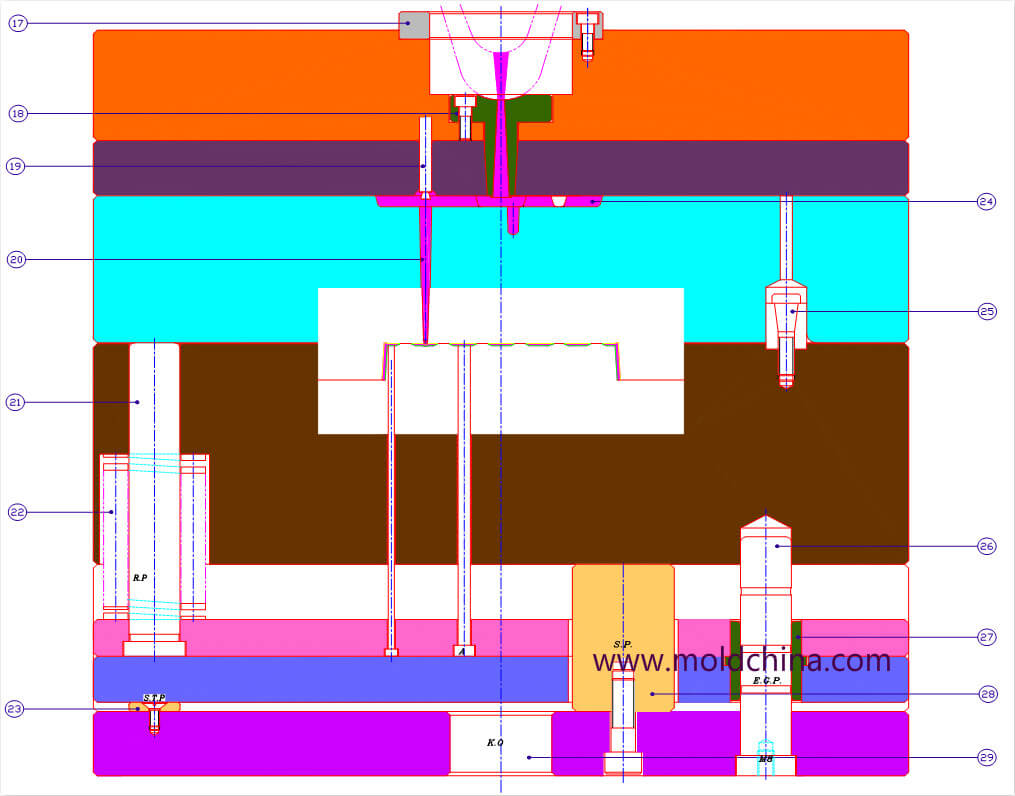

1)The structure of 3 plates mold

17.Locating ring 18.Dowel pin 19.Runner holder 20.Runners systerm 21.Return pin 22.Spring 23.stopper 24.Main runner 25.Nylon locker 26.Guide pin 27.Guide bush 28.Supporter 29.K.O holes

2) How the 3-plate mold works?

- When a 3 plate mold opens, the cavity and the core do not separate from each other at first, but the striper plate will be firstly separated from the cavity plate – the striper plate releases the molded product from the gate material, and then the cavity and the core separate from each other to eject the product.

- Some variations of 2 plates molds are also applicable in 3 plates molds, but the molds are much more complicated.

- One of the variations of a 3-plate mold is its combined application with the runner of a 2 plates mold.

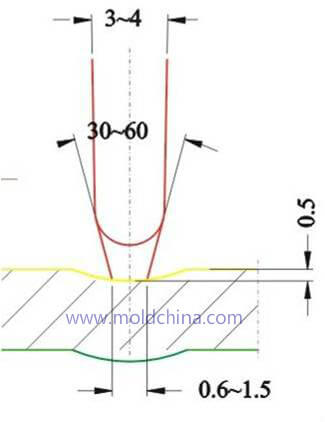

The gate and runner systerm of 3 plate mold

- Pros of a 3-plate mold:

- A 3-plate mold only adopts the pin-point gate system.

- A 3-plate mold leaves very minimal marks on the product; even mark-less injection molding is allowed;

- The gate of a 3 plate mold does not need to be specially removed.

- Cons of a 3-plate mold:

- Since a 3 plates mold features a longer runner, cooling will take a longer time, thus leading to a longer injection cycle;

- A 3 plates mold consumes more materials;

- The structure of a 3 plates mold is relatively more complicated.

if you want to find a professional plastic injection mold manufacturer to make your 3 plates mold,please feel to contact us!