Holding Pressure Setting

(1) The Significance of Pressure Holding/Pack

After the mold cavity is filled, holding pressure is applied to compensate for resin shrinkage caused by cooling. Appropriate holding pressure and holding time will be maintained to push the mold screw, to continue injecting molten resin into the cavity. Holding pressure has a great influence on product shrinkage rate.

(2) Confirmation of Holding Pressure/Time

The level of holding/pack pressure influences the shrinkage rate in plastic injection molding process. Holding pressure can be increased to make the product bigger, thus helpful for shrinkage compensation.

On the contrary, product dimensions will be reduced, leading to shrinkage. However, if the holding pressure is too high, mechanical force and residue stress will be caused, leading to product deformations.

Usually, an appropriate holding/pack pressure is 70 – 80% of the max. injection pressure.

Holding Time: The holding time is correlated to cavity thickness, because a thicker product takes a longer time to cool down. Resin needs to be continuously filled during that period of time, or product shrinkage will occur. However, the molten resin cannot enter the cavity after the gate is solidified. After all, holding time is equal to the solidification time of the gate, so the gate should be appropriately designed based on product thickness. Gate solidification time is dependent on gate thickness and length.

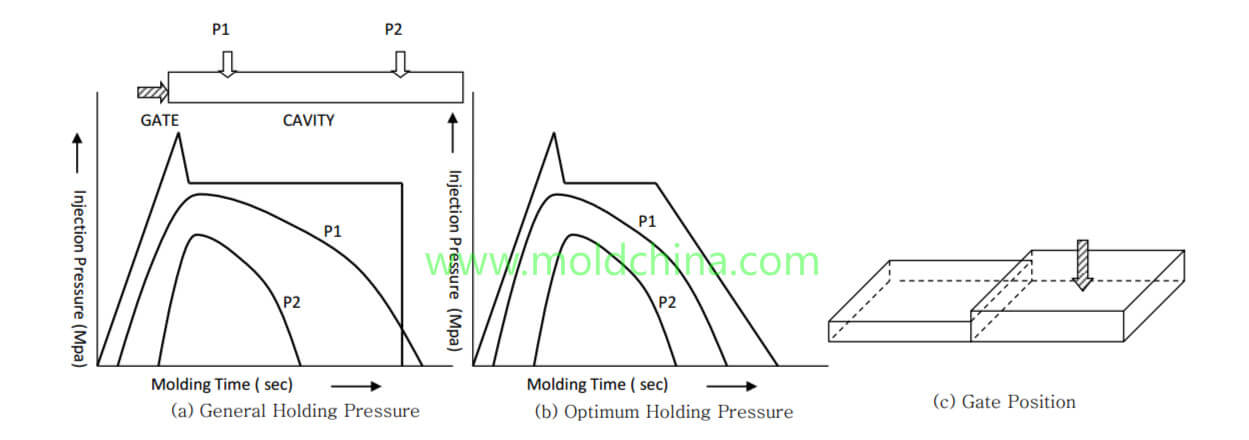

(3) Optimum Holding Pressure Setting

Usually, if the holding pressure is applied at a constant rate, the gate area will be subject to a larger pressure, leading to a lower shrinkage rate; and the furthest end will not receive sufficient pressure, leading to a higher yet uneven shrinkage rate. Such an uneven increase of residue stress is considered an important cause of deformation. Therefore, the holding pressure should not be set in a uniform way, but gradually decreased, to minimize pressure difference within the cavity through several rounds of holding pressure settings.

In addition, the gate should be positioned in the thicker part of the product. Usually, shrinkage rate is dependent on pressure and solidification speed. Locating the gate where the solidification speed is low and the shrinkage rate is high is able to provide sufficient pressure, thus ensuring a uniform shrinkage rate. Holding time should be longer than gate solidification time. If not, the screw will retreat for plasticization (pressure holding is often followed by feeding), the resin material compressed at the front end of the gate will flow back, and subsequently the shrinkage rate around the gate will go up.

All copyright reserved by injection molding factory Sositar Mould