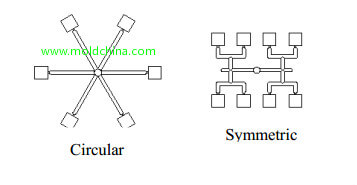

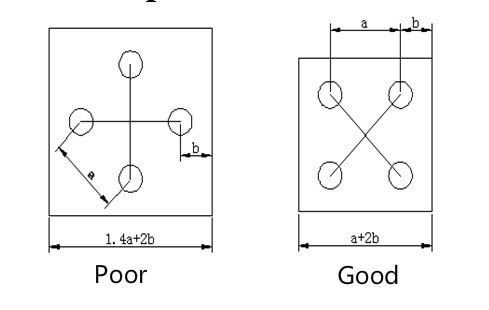

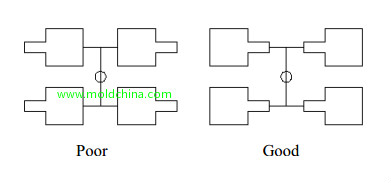

(1) Strive for balance and symmetry in mold layout design

1.Each mold cavity is concurrently filled under the same temperature condition

·Adopt a balanced & symmetric mold layout·

For an asymmetric layout, balance can be achieved through adjustment of gate dimensions

2.Runner balance

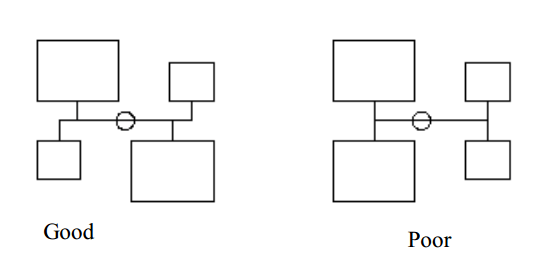

3. Symmetric layout for large & small products

4. Mold force balance, i.e. the center of injection pressure coincides with the center of the main runner, so as to prevent overflow.

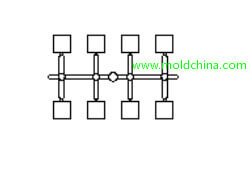

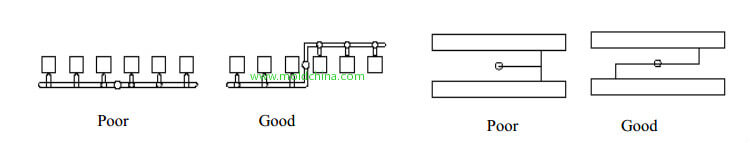

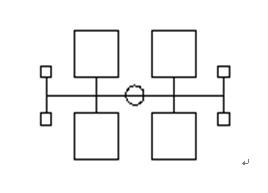

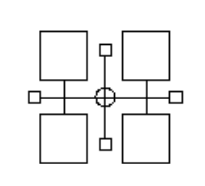

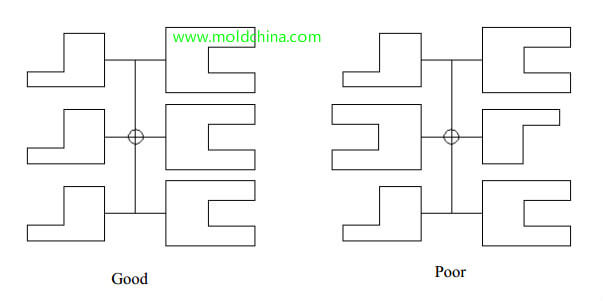

(2) Make the runner as short as possible, to reduce wastage,molding cycle and heat loss. H-shaped layout is better than circular

and symmetric layouts.

(3) Minimize the number of molding cavities for high-precision products, because product precision will drop by 4% with the additionof each cavity. Usually, the number of cavities of a precision mold is no more than four.

(4) The same color & material

(5) Compact structure to save steel material

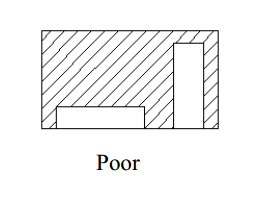

(6) The larger the closer, the smaller the farther

(8) First large then small, with the small appropriately fitted

(9) For the same product, the larger the closer and the smaller the farther

(10) Good technology capability

https://youtu.be/rVBRZzbCDlc