Three plate mold VS Two plate Mold

Appearance difference Between two plate mold and three plate Mold

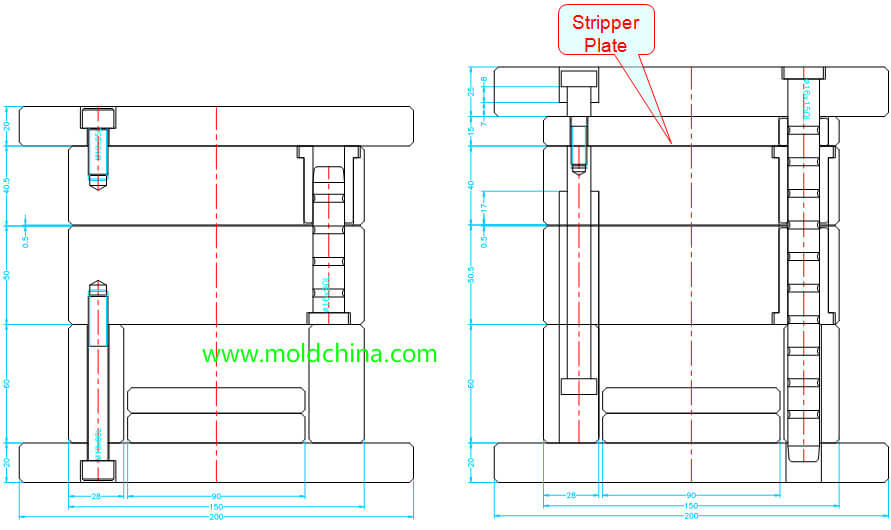

With regard to appearance, the biggest difference between the two plate mold and the three plate mold is that there is a stripper plate between the upper clamping plate and the cavity plate of the three-plate mold.

Structures difference Between 2-plate mold and 3-plate Mold

The main difference in the structure of the molds lies in the location and orientation of the guide pin, and that the three-plate mold has a small tie bar and a nylon lock on parting surface or latch on the side of the mold to control mold opening sequence and stroke.

Applications difference Between 2-plate mold and 3-plate Mold

| 2-Plate Mold | 3-Plate Mold | |

| Mold Size | Average | Larger |

| Mold Production Cost | Low | High |

| Molding Machine Capacity Requirements | Low | High |

| Structural Strength | Strong | Weaker |

| Automatic Production | Semi-automatic / Automatic | Semi-automatic / Automatic |

| Molding Cycle | Short | Long |

| Molding Pressure | Low | Higher |

| Runner weight | Small | Larger |

| Gate Trimming | Dependent on Gate Type | Unnecessary |

Comparison of the Two Mold Structures

We can clearly see from the comparison in the above table that a two-plate mold is better than a three plates mold in most aspects, but why is there a three-plate mold in mold making and design? How to make a choice during design?

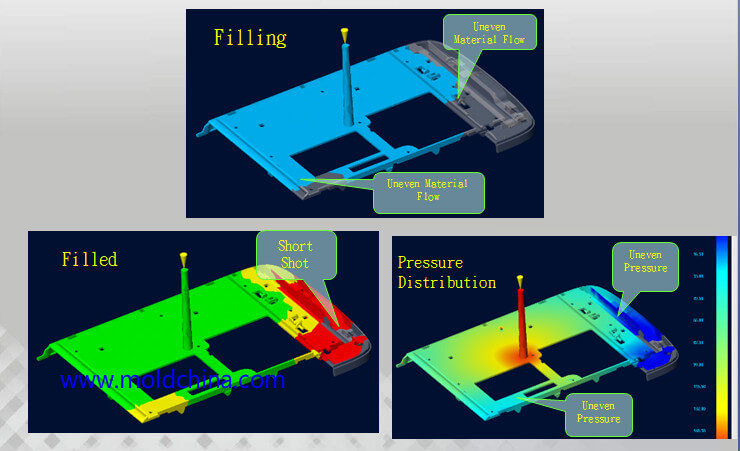

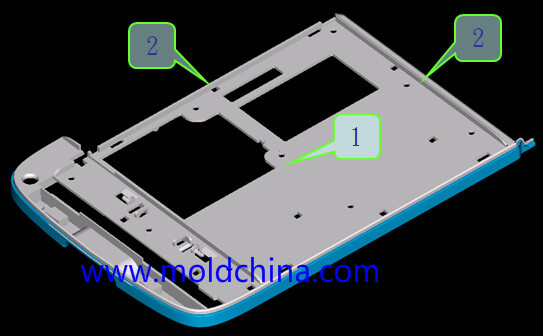

A three plates mold mainly exists in response to the appearance and production requirements of plastic products. For the finished product on the drawing, if the design is implemented through a two plates mold, the following two filling methods are available:

- The first filling method is to directly inject material through the large points on the finished product surface.

- The second method is to fill material from the non-appearance surface of the finished product (there is a location for consideration).

We can clearly see in the three mold flow analysis diagrams on the right that there are such problems as uneven flow, uneven pressure and short shot. There is no need to explain the short shot. Under uneven plastic flow and uneven pressure, though the mold is completely filled, the finished product will be severely deformed after molding. Next, it is necessary to consider the trimming problems of the finished product after molding (the trimming of the gate and the finished product) and whether the residue gate interferes with other matching components due to protruding from the product surface, which in turn affects assembly.

As can be clearly seen from the drawing, mold filling is directly carried out from the side of the finished product. At this time, in addition to obvious short shot, there is still a situation in which the flow is uneven.

During mold trial, the molding factory will increase the injection pressure and accelerate the injection speed in order to fully fill the finished product. At this time, the excessive injection pressure will most likely cause the mold to overflow. If so, this will greatly affect the service life of mold production.

In addition, because of the lateral feeding, the finished product must be placed in a location away from the mold core; in order to reduce the size, the mold must be designed into an eccentric one; as a result, in addition to mold cost rise, it may cause an increase in the capacity of the molding machine, which indirectly increases the production cost of the molding factory.

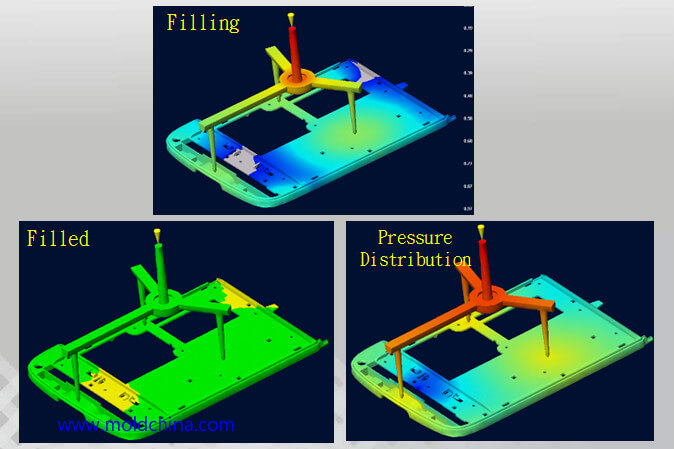

In the three diagrams on the right, we can clearly see the difference in its injection molding conditions with that of the two-plate mold. The material flow is also obviously more even than the single point filling, and the short shot phenomenon is gone. Although pressure distribution is still not even enough, we can adjust the pressure distribution by controlling the size of the filling point.

In terms of molding pressure, the injection pressure of the three-plate mold is not much higher than that of the two-plate mold under the situation of complete filling. The main reason is that for the finished product, single-point filling is more difficult for plastic feeding.