Warpage

Warpage is caused by shrinkage variations throughout the part.

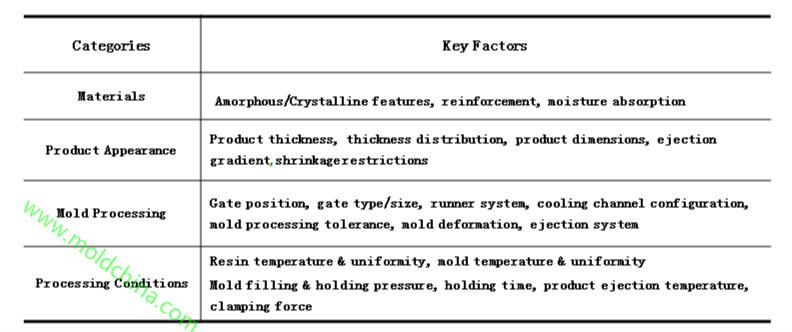

Warpaging is mainly caused by:

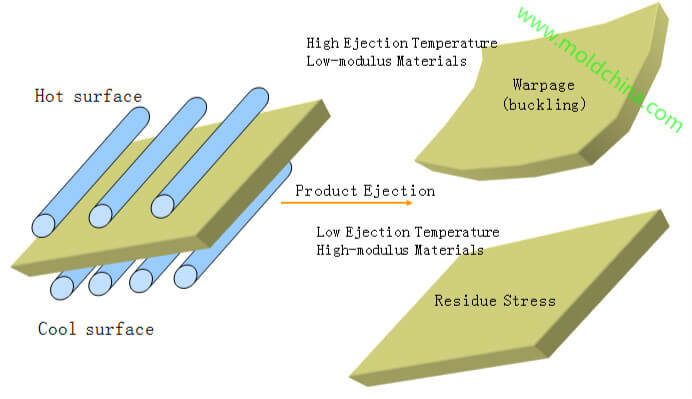

– The cooling time difference caused by the temperature difference between the upper and lower surfaces of the mold, which causes difference in internal residue stress.

– The pressure (injection pressure, holding pressure) difference inside the product will be reflected as a non-uniform shrinkage rate.

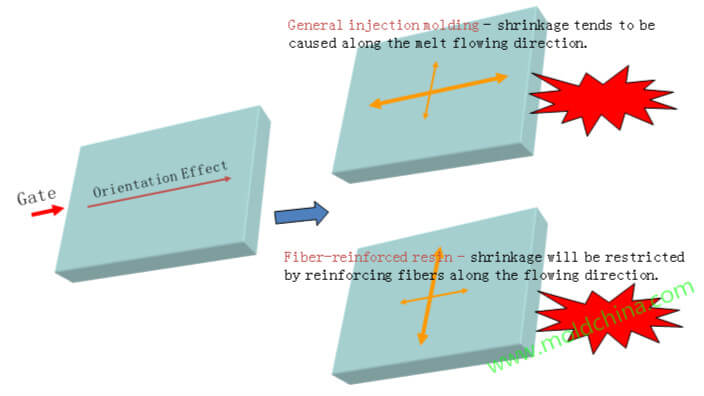

– The orientation difference between resin flowing direction and the direction perpendicular to flow will be reflected as residue stress.

Proper product review

During product design or mold design, review the items that help improve dimensional stability

- Orientation effect caused by resin flowing direction

- Effect caused by cooling difference between upper/lower surfaces

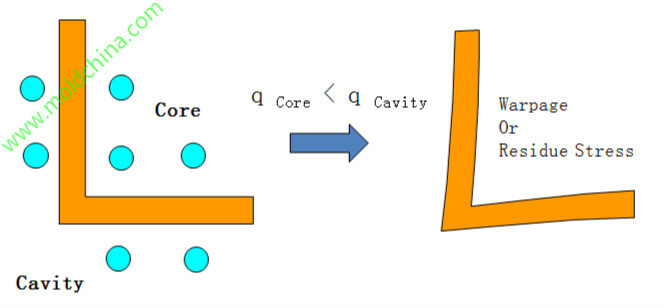

- Effect caused by cooling difference (Corner Effect)

Since it is more difficult to cool the core than to cool the cavity, after ejection, larger shrinkage tends to be caused on the core side of the product.

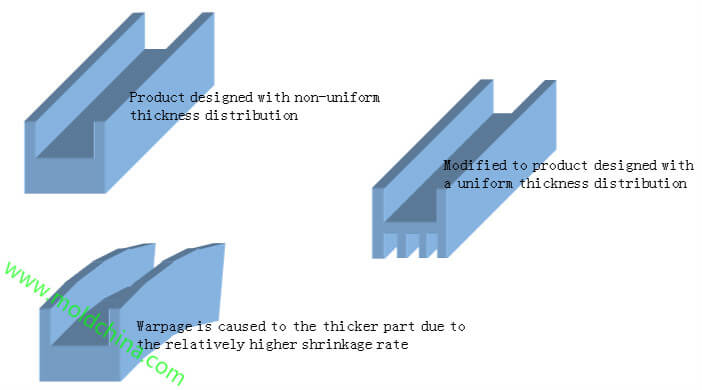

- Influence of uniformity in product thickness

- Warpage caused by pressure difference in the cavity